In India’s rapidly advancing industrial landscape, the demand for speed, consistency, and precision in fabrication is growing every day. With thinner margins, tighter delivery schedules, and global competition, traditional welding methods alone are no longer enough.

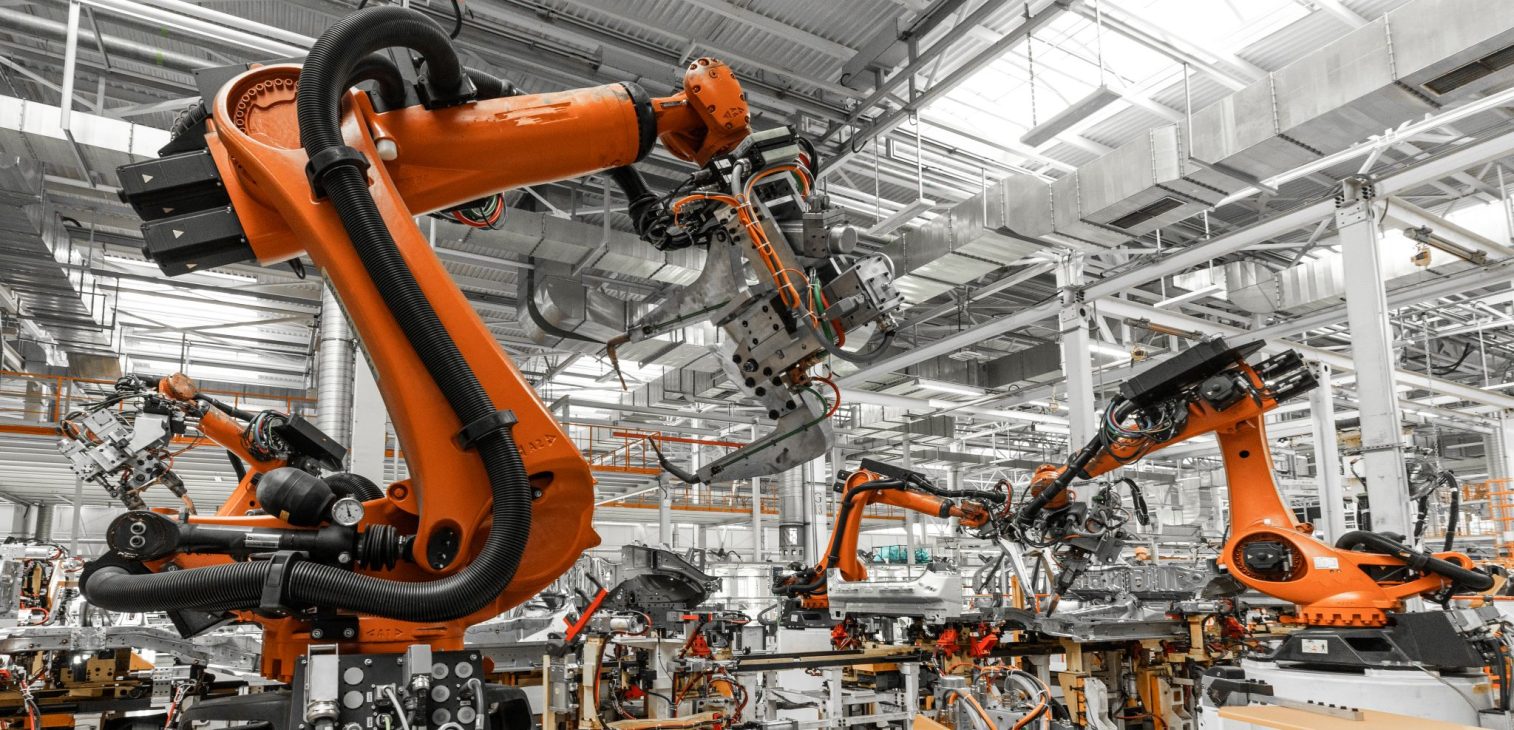

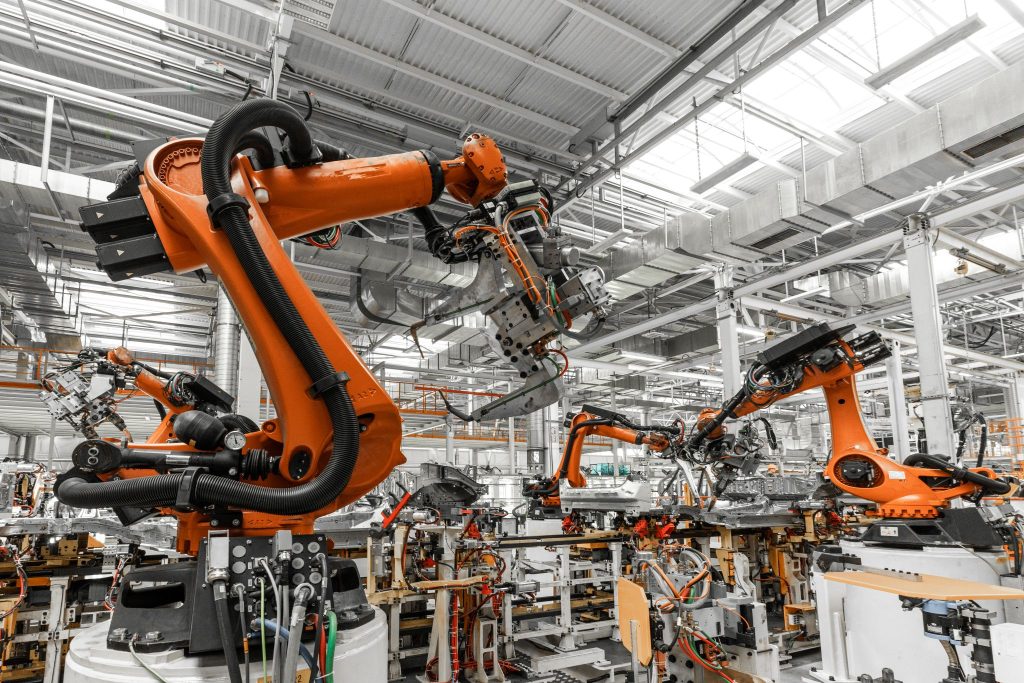

Industries need more than just robotic arms — they need integrated automation systems that do the heavy lifting with flawless precision.

That’s where StarBlaze comes in — delivering complete welding automation solutions built for the real-world challenges of Indian manufacturers. From robotic arms and power sources to jigs, sensors, safety features, and programming, we offer everything needed to automate welding, end-to-end.

Why Automation is the Future of Welding

Welding remains the backbone of industries like automotive, railways, steel, heavy engineering, and infrastructure. But relying solely on manual welding means dealing with:

- Inconsistent weld quality

- Higher chances of rework or failure

- Operator fatigue and safety risks

- Slower production cycles

Robotic and automated welding systems solve these issues by offering:

- Precision – repeatable, high-quality welds

- Productivity – faster cycle times and 24/7 operation

- Safety – minimal human exposure to heat, sparks, or fumes

- Efficiency – reduced material waste and error

In short, automation isn’t just about replacing manpower — it’s about unlocking smarter production.

StarBlaze: More Than Robots — We Deliver Full Automation Ecosystems

At StarBlaze, we go beyond supplying robotic welding arms. We build tailored, turnkey automation solutions based on your process, part geometry, and production goals.

Whether you’re in automobile parts, railway components, structural fabrication, or OEM manufacturing, StarBlaze helps you scale up your production line — with complete support from design to commissioning.

Automation for Every Stage of Growth

One of the biggest barriers to automation is the misconception that it’s only for large factories. That’s no longer true.

StarBlaze offers scalable automation packages for:

- Large enterprises aiming to modernize entire fabrication lines

- Mid-size shops upgrading select welding stations

- Growing MSMEs that want to start with modular robotic cells

Every solution is designed to be:

- Modular – add more stations as you grow

- Customizable – we design around your current layout

- Trainable – your team can operate and troubleshoot with ease

We believe in making smart manufacturing accessible to every Indian industry.

Real Results, Real Impact

Companies that have adopted StarBlaze welding automation have reported:

- Up to 30% reduction in cycle times

- Significant cost savings from reduced rework

- Enhanced weld quality for global exports

- Improved worker safety and redeployment to skilled tasks

Whether you’re fabricating a truck chassis, boiler panel, or precision components, automation improves not just output — it improves your competitive edge.

Smarter Welding Starts Here

India’s industrial future is being built today — and it needs smarter, faster, and safer welding systems to support it. With our complete automation offering, StarBlaze is powering that change — from plant floors to production lines across sectors.

So if you’re thinking about automating your welding — think beyond the robot.

Think full system integration. Think StarBlaze.

Because when you’re building the future, it pays to be Smarter With StarBlaze.