Pinaka QD Primer 1430

Pinaka QD Primer 1430 is a quick-drying, single-component alkyd primer developed for automotive refinishing and industrial metal applications. Designed for short recoating cycles, it offers excellent surface dry and touch dry times, making it perfect for fast-paced workshops and production lines.

Compatible with NC lacquers and quick-drying enamels, it provides uniform film build, good adhesion, and ease of application over cleaned bare metal surfaces.

Available Packs: 1L, 4L, 20L

Key Features

- Fast surface dry in 10–15 minutes

- Excellent adhesion on bare or cleaned metal

- Compatible with NC lacquers and fast synthetic enamels

- Easy-to-use single component formula

- Semi-glossy or matte finish options available

- Withstands temperatures up to 100°C

Industries

- Automotive Refinish Workshops

- Metal Component Manufacturers

- Light Industrial Equipment

- Fabrication & Assembly Lines

- Quick Maintenance & Repair Shops

Processes

- Vehicle Panel Priming

- Fast Cycle Industrial Basecoating

- Undercoat for Enamel or NC Finishes

- Metal Refurbishment Projects

- Spot Repair & Repainting

Tab Title

- Mixing Ratio: Single-component; ready to use

- Refer TDS for more details

Related Products

-

Pinaka Etch Primer 709 is a two-component, low-viscosity primer formulated with zinc tetroxy chromate for superior bonding on galvanised and bare metal surfaces. It microscopically etches the substrate to improve intercoat adhesion, forming a reliable base for further coatings. Ideal for use on galvanised sheets, aluminium, and stainless steel, the product conforms to IS 5666 and is designed for industrial applications where coating life and adhesion are critical. Available Packs: 1L, 4L, 20L

-

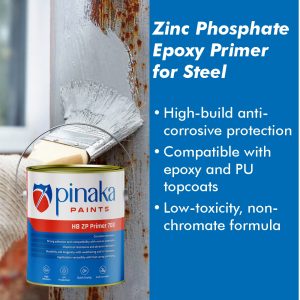

Pinaka ZP Primer 708 is a two-component, polyamide-cured epoxy primer formulated with zinc phosphate for high-build corrosion protection. Suitable for both blast-cleaned and manually prepared steel, it provides excellent chemical resistance and long-term durability in aggressive industrial environments. The non-chromate, low-toxicity formulation makes it a safer alternative for steel treatment, while ensuring deep penetration, strong adhesion, and excellent compatibility with epoxy and polyurethane topcoats. Available Packs: 1L, 4L, 20L

-

Pinaka HTC-600 801 is a high-performance, single-component aluminium-pigmented silicone coating designed to reduce radiant heat loss and guard against high-temperature corrosion. It forms a bright, reflective ceramic barrier that minimises heat transfer and condensation on industrial equipment operating at temperatures up to 600°C. Formulated with insulating microspheres and silicone co-polymers, it delivers measurable energy savings and surface temperature drops. The self-priming formula eliminates the need for a separate base coat, simplifies application, and contributes to faster heat-up times. Ideal for boilers, furnaces, and manifolds where energy efficiency and long-term protection matter. Available Packs: 1L, 4L, 20