E71T-1

E71T-1 is a high-performance, all-position gas-shielded flux-cored welding wire engineered for both single and multi-pass welding on mild and low alloy steels. It offers exceptional arc stability, low spatter, easy slag removal, and excellent weld bead appearance. Designed for high productivity applications in structural steel fabrication, the wire is vacuum-packed for rust-free storage and superior shelf life.

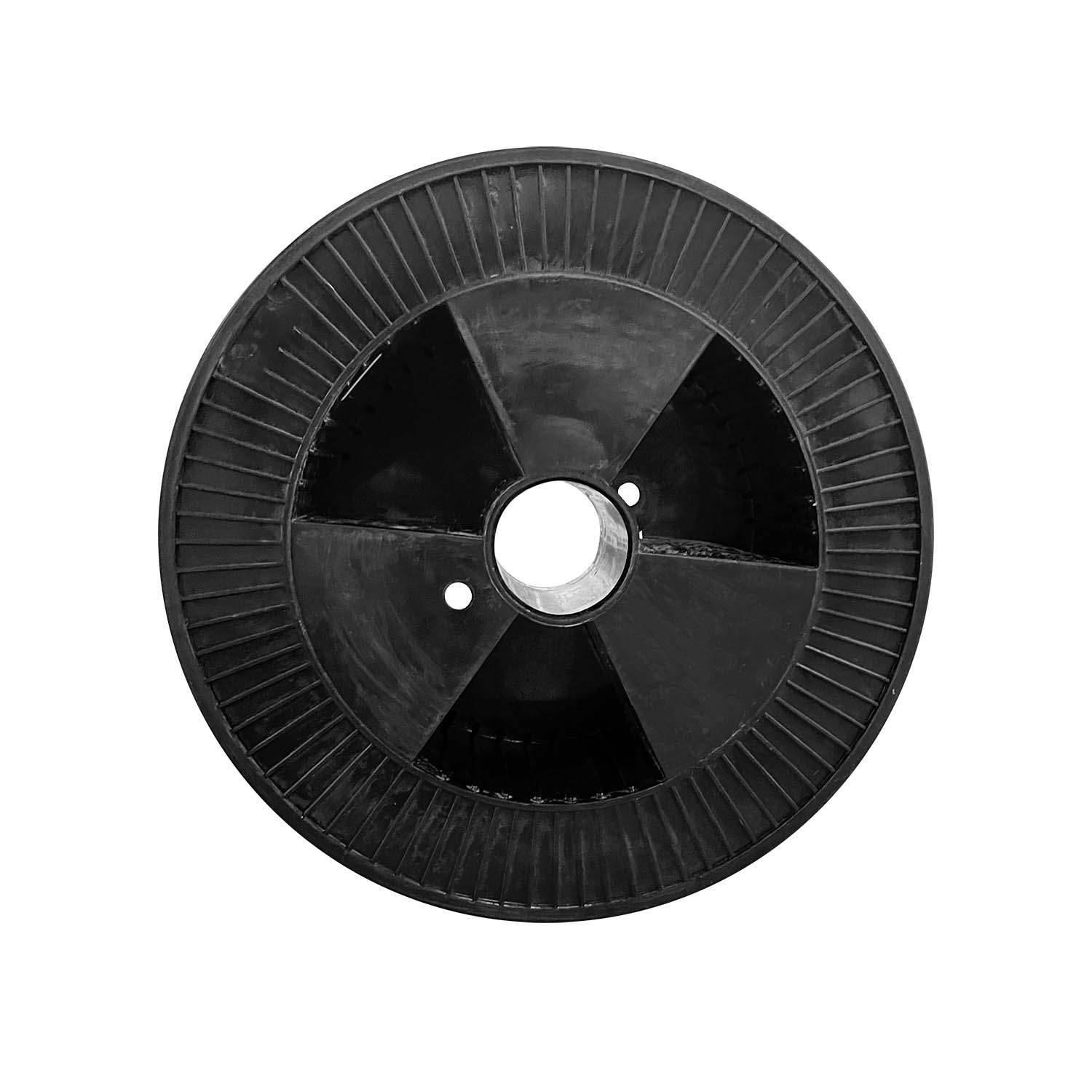

Available Sizes & Packaging

| Wire Diameter | Packaging Type | Pack Size |

|---|---|---|

| 1.20 mm | Vacuum-packed spools | 15 kg/spool (standard) |

| 1.60 mm | Vacuum-packed spools | 15 kg/spool |

| Other sizes | On request (MOQ applies) | Custom spool sizes available |

Shelf Life: 12+ months (in original vacuum pack, unopened)

Storage Note: Keep in dry and cool storage to prevent premature rusting.

All-position welding (F, V-up, O, H)

Smooth arc transfer and excellent arc stability

Low spatter and easy slag removal

Low fume emission for operator comfort

High deposition efficiency with good penetration

Excellent bead shape and weld finish

Vacuum-sealed packaging to prevent rusting

Consistent mechanical properties

Low diffusible hydrogen (≤ 5 ml/100g)

Generator-compatible and field-proven reliability

Shipbuilding & Offshore

Bridges & Infrastructure Projects

Heavy Equipment & Machinery Manufacturing

Petrochemical Plants

Storage Tanks & Pressure Vessels

Power Plants & Boilers

General Structural Steel Fabrication

FCAW-G (Flux Cored Arc Welding – Gas Shielded)

All-position welds for structural and fabrication use

Designed for CO₂ or Ar/CO₂ shielding

Ideal for both manual and semi-automatic operations

Suitable for mild and low alloy steels (up to 500 MPa tensile strength)

Product Details

| Property | Typical Value |

|---|---|

| AWS/ASME Classification | E71T-1C/1M |

| Shielding Gas | 100% CO₂ or Ar/CO₂ Mix |

| Welding Positions | All Positions (F, V-up, O, H) |

| Yield Strength | 500 N/mm² |

| Tensile Strength | 600 N/mm² |

| Elongation | 28% |

| Impact Strength | ≥ 27 J at -20°C |

| Diffusible Hydrogen | ≤ 5 ml/100g |

| Typical Chemistry | C ≤ 0.12, Mn ≤ 1.75, Si ≤ 0.90, S ≤ 0.03, P ≤ 0.03 |

Raise a Quote

Related Products

-

AWS A5.1: E6013 | DIN EN ISO 2560-A: E 38 0 R 12 | IS 814: ER 4221X Radiographic Weld Quality, Smooth Bead Appearance, Site Current Tolerance Rutile medium-coated electrode for structural and pipe welding where precise fit-up and site variability are common. Delivers a forceful yet soft arc, finely rippled weld appearance, and consistent usability across variable current conditions. Optimised for radiographic-quality welds in shipbuilding and construction.

- Available Packs

- Dimensions: 2.50 mm x 350 mm, 3.15 mm x 450 mm, 4.00 mm x 450 mm

- Pack Sizes: 2.5 Kg Pouch, 5 Kg Box

- Master Box: 20 Kg, 30 Kg, 40 Kg, Customisable packaging available on request

- Available Packs

-

AWS A5.4: E309-15 | DIN EN ISO 3581-A: E 23 12 B 22 | Werkstoff Nr: 1.4332 Buffer-Layer Ready, Smooth Fusion, Ideal for Carbon to Stainless Welding Basic-coated stainless steel electrode with ~15% ferrite, designed for welding dissimilar metals and overlaying high-temperature steels. Suitable for buffer layers before hardfacing and 18/8 cladding. Delivers smooth fusion, easy slag release, and strong impact resistance. Trusted for repair, civil engineering, and fabrication applications.

- Available Packs

- Dimensions: 2.50 mm x 350 mm, 3.15 mm x 450 mm, 4.00 mm x 450 mm

- Pack Sizes: 2.5 Kg Pouch, 5 Kg Box

- Master Box: 20 Kg, 30 Kg, 40 Kg, Customisable packaging available on request

- Available Packs

-

AWS A5.1: E 6010 | EN 499: E 38 3 C 21 | DIN EN ISO 2560-A: E 38 3 C 21 Deep Penetration, Fast Freezing, Radiographic Quality Welds High cellulose-coated deep penetration electrode for radiographic-quality welds. Suitable for all-position welding of pipes and pipelines using stove pipe and conventional techniques. Delivers strong arc force, rapid freeze characteristics, and excellent mechanical properties. Available Packs

-

- Dimensions: 2.50 mm x 350 mm, 3.15 mm x 450 mm ,4.00 mm x 450 mm

- Pack Sizes: 2.5 Kg Pouch, 5 Kg Box

- Master Box: 20 Kg, 30 Kg, 40 Kg, Customisable packaging available on request

-